INDIGO DYEING

Indigo is a vat dye. To get the dyestuff onto the yarn or the fabric, it's solubilised in water with the help of a reducing agent. When the yarn or fabric is pulled out of the dyeing vat, and gets in contact with the atmospheric oxygen, the oxidation process binds the colour molecules to the fibres of the yarn.

Regarding raw material, 95% of raw material is cotton that already we tested atmospheric plasma effect on it and know that it will increase wettability so much. In other textile finishing line, are used different material or mix at same time. For example, cotton/polyester, Acrylic/wool, viscous or etc and we cannot consider same machine configuration for all. But for Denim we have cotton and indigo dying almost forever.

Since Surface of denim dyed , it is not necessary (should not) to dye core of yarn (fabric) so it is the best compatibility with corona and rotor spray concept because they are focusing on the surface.

Using Ozone as a bypass product can be used in oxidation of indigo dyeing and increasing of production speed and reduce cost of oxidation facilities

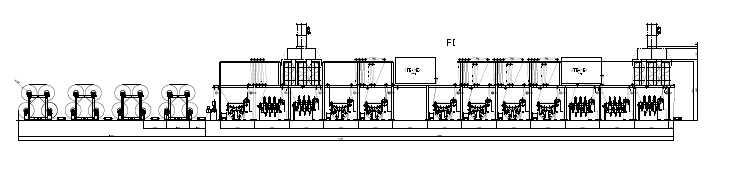

since this machine can use in first of denim line so it can easy insert in first of indigo line and be installed without big changing in production line thus we can offer to denim factories directly