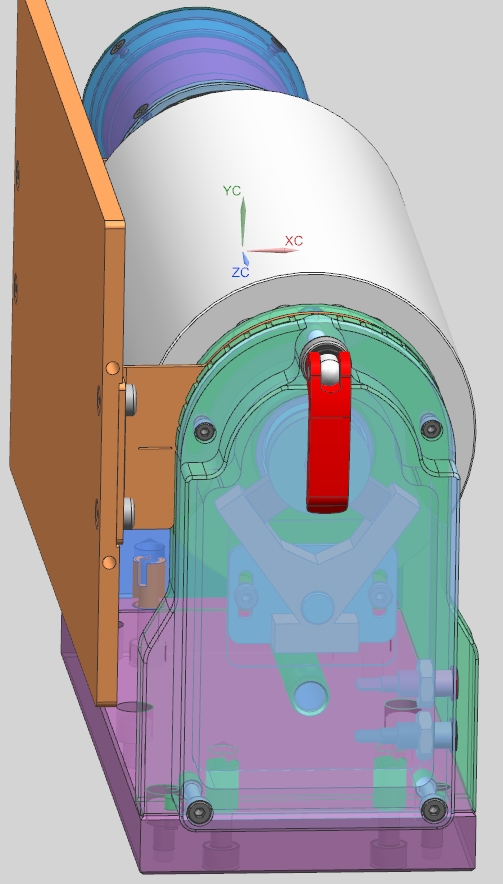

Drum Collector

In the field of electrospinning, the drum collector is a pivotal component used to produce uniform nanofibrous mats. This collection module is designed with a rotating drum that is equipped with a rotation speed control and display unit, allowing for precise adjustments and monitoring during the electrospinning process.

Functionality and Features

The primary function of the drum collector is to provide a controlled surface on which randomly oriented nanofibers are deposited. As the drum rotates, the electrospun fibers are continuously collected, forming a non-woven mat with uniform thickness and density. The rotation speed can be adjusted to influence the deposition rate and the overall properties of the nanofibrous mat.

- Rotation Speed Control: The rotation speed control is a crucial feature that enables the fine-tuning of the drum’s speed. By adjusting the speed, researchers can control the rate of fiber deposition and the degree of fiber alignment. Typically, lower speeds result in more random fiber orientations, while higher speeds can induce some level of alignment, although not as pronounced as with other types of collectors.

- Display Unit: The display unit provides real-time feedback on the rotation speed, ensuring that the process parameters are accurately maintained. This feature is essential for reproducibility and consistency in the production of nanofibrous mats.

Advantages

- Uniform Fiber Deposition: The rotating drum ensures that nanofibers are evenly deposited across the surface, leading to a uniform mat. This uniformity is critical for applications where consistent material properties are required.

- Scalability: Drum collectors can be scaled to accommodate larger surface areas, making them suitable for both laboratory-scale and industrial-scale production.

- Versatility: Suitable for a wide range of polymers and solvents, drum collectors are versatile and can be used to produce nanofibrous mats from various materials.

Applications

The drum collector is widely used in several applications due to its ability to produce uniform and consistent nanofibrous mats:

- Filtration: In the development of high-efficiency filters for air and water purification, where uniform fiber distribution is essential for optimal performance.

- Biomedical Engineering: For creating scaffolds used in tissue engineering, wound dressings, and other medical applications where consistent fiber mats are needed.

- Textiles: In the production of advanced fabrics with enhanced properties such as breathability, durability, and lightweight characteristics.

- Energy Storage: For fabricating electrode materials in batteries and supercapacitors, where uniformity in the fiber structure can improve performance.

Conclusion

The drum collector is an indispensable tool in the electrospinning process, offering the ability to produce uniform nanofibrous mats with controlled deposition. Its rotation speed control and display unit provide precision and reliability, making it a versatile and scalable option for a wide range of applications in research and industry.